Tooling

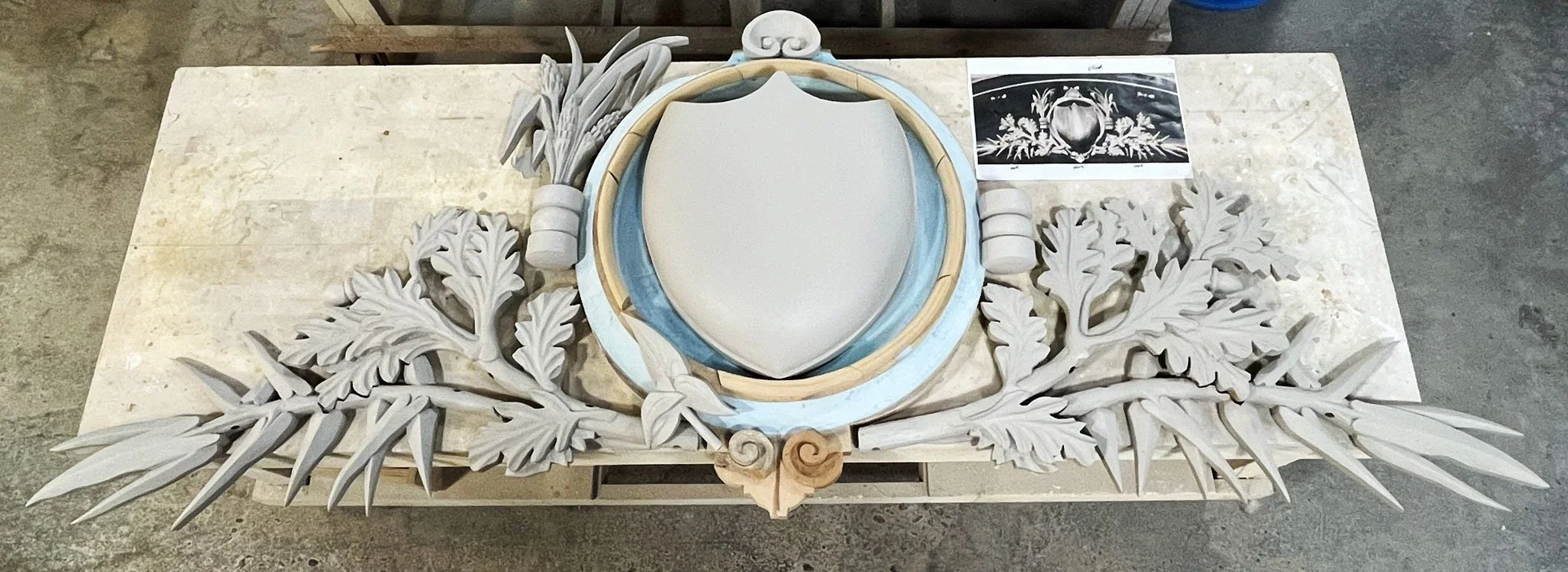

Our model- and mold-making capabilities combine traditional craftsmanship with advanced technologies. From clay and plaster sculpting and wood pattern work to CNC-machined models, we employ a range of methods.

Whether we are able to start with damaged but whole originals, partial castings, or have only historic photos or drawings to build from, we can select the most appropriate approach for each project.

Because practically all of our tooling is custom, we are highly skilled at developing molds that balance the needs of performance, durability, and economy. This expertise allows us to create efficient solutions for even the most complex geometries.

We often support projects beyond our own production facilities. We can provide tooling and design services to other pre-casters, contractors, and regional producers, often reducing transportation costs, supporting local production, and contributing to LEED goals.